Case

750 tons of PPE. No capacity. Tight deadline. This is how it’s done

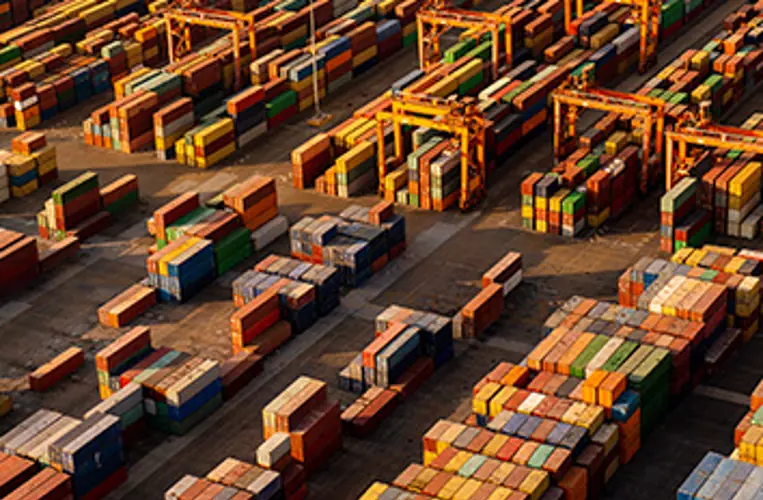

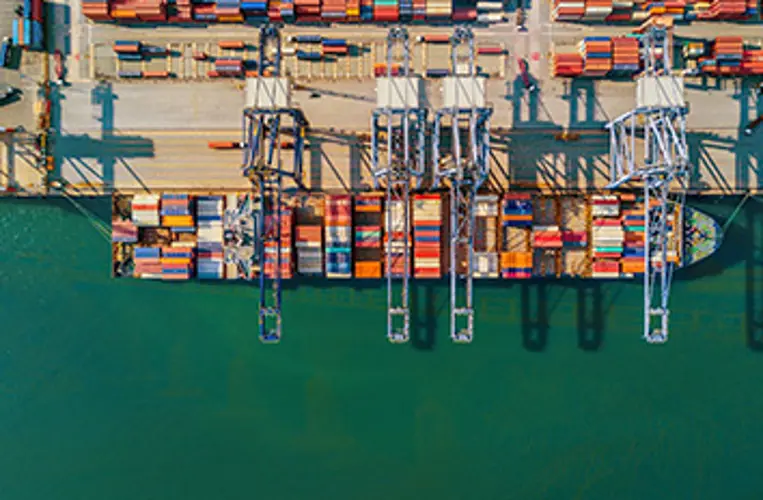

The math was simple. Delivering 750 tons of cargo in a deadline of under three weeks in peak season required us to locate available aircraft capacity that could support this project. Given the current capacity constraints in the hottest airfreight market in history, finding the required aircraft posed an enormous challenge. Leveraging on local expertise, using every resource available, our Asia Pacific team used great creativity to build an individually tailored solution within days for the customer. Across multiple time zones, plans were initiated, coordinated, and monitored 24/7 to ensure an uplift from various airports, resulting in cargo moving across 21 consecutive days via proactive partner carriers.

Push-back from the start

Right from the start, problems were competing for attention. At first, the PPE faced some production delays and changes against schedules, resulting in factory release times impacting planned (and contracted) flight programs. This situation caused a knock-on effect, moving collection times, flight planning, quality checks, and customs clearance processes.

Despite difficulties, the products kept moving, ensuring a continual daily flow of goods.

Airport congestion was not going to stop our performance

However, upon arrival, congestion was plaguing arrival facilities. A tailored program was designed with our airline partners to minimize the impacts for the customer upon arrival. At the same time, a proactive communication flow via our Control Tower kept the customer continuously informed of changes for their planning.

Consequently, significant volumes moved seamlessly through cargo facilities to keep continuity in the delivery process and support the on-time delivery.

A massive undertaking during difficult times

Though facing record levels of demand in the market, a close collaboration with the customer, regional offices, the supplier, and our partners kept the product moving to achieve the customer’s desired outcome – meeting their contractual commitments.

A strong dedication to always finding the right solution paved the way for solving a remarkable project in a unique period for global logistics.

Where others couldn’t find the required aircraft and timeframes, we could.

Read the latest news on your future solutions in action

The task was clear: Ship humanitarian aid from Manila to Myanmar – asap!

Building SGL Asia’s growth engine

A partnership built on shared ambitions and values

SGL humanises acquisitions

Critical space availability solved through close supplier ties

From local to global, with the core intact

Moving forward despite headwind

Sourcing weekly allocations in a low-capacity market

Customised solutions to avoid blank sailings